Unlocking the Secrets of Donahue V Rodd Electrotype: A Beginner’s Guide

Legends often surround the name Donahue V Rodd Electrotype, leaving many clueless about its true nature and potential. This comprehensive guide aims to unveil the mysteries, revealing its applications, history, and hidden secrets.

Victoria Daily Photo: Esquimalt Lagoon – Source victoriadailyphoto.blogspot.com

Donahue V Rodd Electrotype emerged as a revolutionary solution to the challenges faced in industries such as printing, electroplating, and electronics.

Jeanne Lanvin and Castillo Silk Scarf The Letters in Blue and Purple – Source www.1stdibs.com

Applications of Donahue V Rodd Electrotype

Donahue V Rodd Electrotype is renowned for its versatility, catering to various applications across different sectors. It excels in creating highly detailed molds, enabling the precise reproduction of intricate designs. Additionally, its ability to produce thin, durable metal sheets makes it ideal for electroplating, where a thin layer of metal is deposited on a surface for enhanced durability and conductivity.

10239_Holzkugeln_Regenbogen_v3.jpg – Source gi.esmplus.com

What is Donahue V Rodd Electrotype?

At its core, Donahue V Rodd Electrotype is an electrochemical process that utilizes a metal mold and an electrolyte solution to create a duplicate or original object. The process involves immersing the mold in the electrolyte and applying an electrical current, causing the metal to deposit on the mold’s surface, replicating its intricate details.

Timeless Failsworth Hats – Davids of Haslemere – Source davidsofhaslemere.com

History and Myths of Donahue V Rodd Electrotype

The origins of Donahue V Rodd Electrotype can be traced back centuries, with its roots in the field of electroplating. Over time, it evolved into a specialized technique used in various industries. However, its shrouded past has given rise to various myths and misconceptions surrounding its origins and capabilities.

Carl Donahue | Ann Arbor District Library – Source aadl.org

Hidden Secrets of Donahue V Rodd Electrotype

Beyond its practical applications, Donahue V Rodd Electrotype possesses hidden secrets that contribute to its exceptional results. The process involves carefully controlling the electrical current, electrolyte composition, and temperature to achieve the desired metal deposition rate and quality. Understanding these intricacies allows for precise tuning of the electrotype to meet specific requirements.

Rodd & Gunn The Gunn Cap – Davids of Haslemere – Source davidsofhaslemere.com

Recommendations for Donahue V Rodd Electrotype

To harness the full potential of Donahue V Rodd Electrotype, it is essential to consider various factors. The choice of metal mold, electrolyte solution, and electrical parameters should be carefully evaluated to ensure optimal results. Additionally, proper preparation of the mold surface and post-processing techniques play a crucial role in achieving high-quality electrotypes.

Tilly Lucas-Rodd – OMP Sports Management : OMP Sports Management – Source ompsports.com.au

Understanding the Electrolyte Solution

The electrolyte solution used in Donahue V Rodd Electrotype significantly impacts the electroplating process. It can influence the deposition rate, metal distribution, and surface finish of the electrotype. Choosing the appropriate electrolyte for the desired metal and application is essential to ensure optimal results.

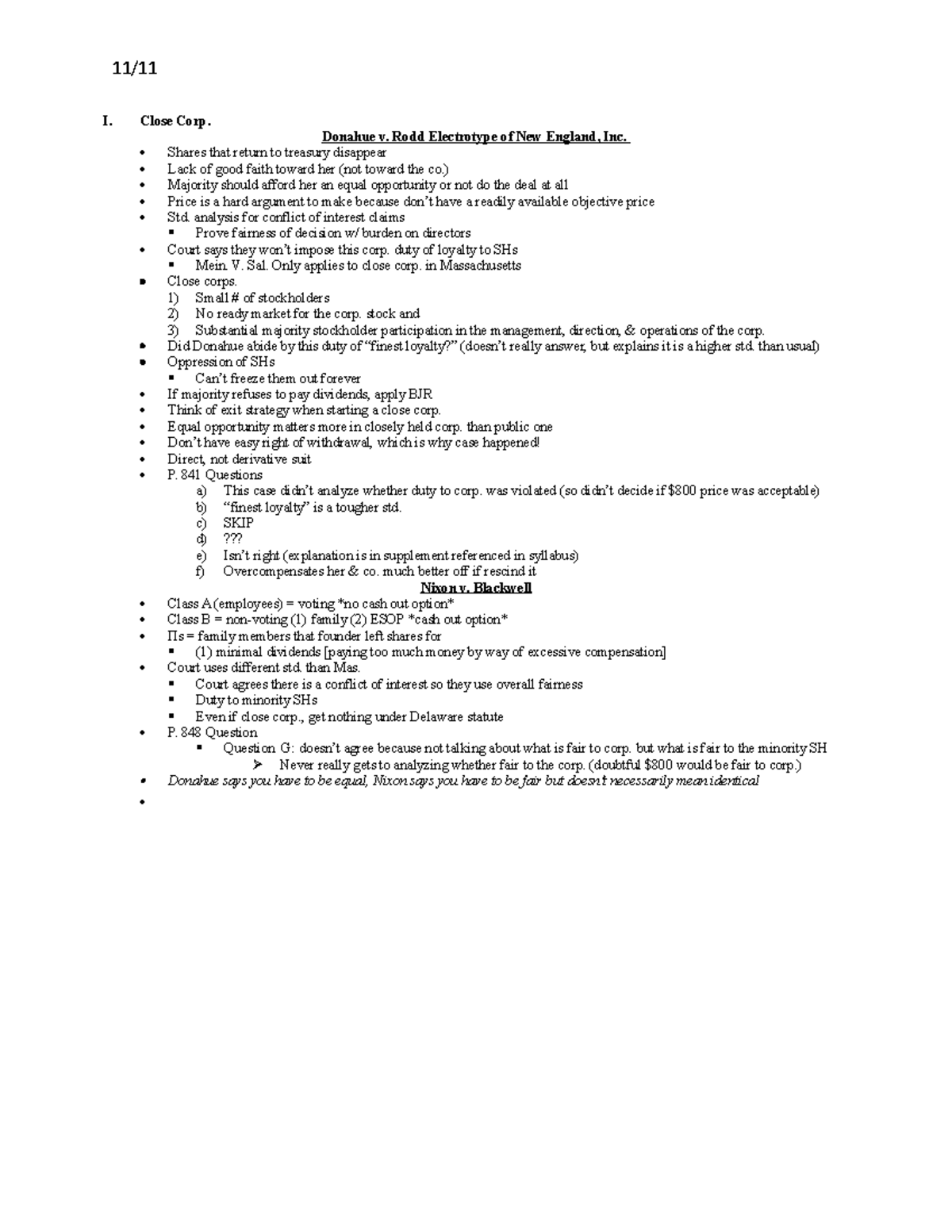

11:11 Notes – Corporations – 11/ I. Close Corp. Donahue v. Rodd – Source www.studocu.com

Tips for Donahue V Rodd Electrotype

Mastering Donahue V Rodd Electrotype requires attention to detail and a keen understanding of the process. Some valuable tips include maintaining a clean and well-prepared mold surface, using a stable electrical current, and ensuring proper ventilation. Monitoring the electrolyte solution regularly and adjusting it as needed is also crucial for successful electrotyping.

PumaUltraUltimateCageTurf-Coral-Salmon_Side1.png?v=1669682746 – Source www.prosoccer.com

Electrolyte Maintenance

Regular monitoring and maintenance of the electrolyte solution are essential to prevent contamination and ensure optimal electroplating results. This includes checking the pH level, specific gravity, and metal concentration, and making necessary adjustments to maintain the desired solution composition.

Hazel Lee Donahue | Obituary – Source www.familiesfirstcare.com

Fun Facts about Donahue V Rodd Electrotype

Donahue V Rodd Electrotype is not just a technical process but also has fascinating historical and cultural aspects. It has been used to create replicas of priceless artifacts, preserving cultural heritage. Additionally, it is employed in the production of jewelry, decorative items, and even medical devices.

How to Master Donahue V Rodd Electrotype

Becoming proficient in Donahue V Rodd Electrotype requires a combination of theoretical knowledge and practical experience. In-depth understanding of the process, including the chemistry, electroplating techniques, and safety precautions, is essential. Additionally, hands-on practice and experimentation with different parameters allow for fine-tuning and optimization of the electrotype process.

What if Donahue V Rodd Electrotype Fails?

Despite careful planning and execution, Donahue V Rodd Electrotype can sometimes fail to produce the desired results. Factors such as contamination, insufficient electrical current, or improper mold preparation can lead to defects. Troubleshooting and identifying the root cause of the failure are crucial for rectifying the issue and achieving successful electrotyping.

Listicle of Donahue V Rodd Electrotype Benefits

Donahue V Rodd Electrotype offers a multitude of benefits, including:

- Precise reproduction of intricate designs

- Production of thin, durable metal sheets

- Enhanced durability and conductivity through electroplating

- Versatility across various industries

- Creation of replicas for cultural preservation

Question and Answer

- What is the key difference between Donahue V Rodd Electrotype and traditional electroplating?

Donahue V Rodd Electrotype focuses on creating solid metal duplicates, while traditional electroplating aims to deposit a thin layer of metal on a surface. - Can Donahue V Rodd Electrotype be used for large-scale production?

Yes, Donahue V Rodd Electrotype is suitable for both small-scale and large-scale production, depending on the size of the mold and electroplating setup. - What are the common materials used in Donahue V Rodd Electrotype?

Various metals can be used, including copper, nickel, gold, silver, and alloys, depending on the desired properties and application. - How can I ensure the quality of the Donahue V Rodd Electrotype?

Careful preparation of the mold, proper electrolyte maintenance, and monitoring of the electroplating process are crucial for achieving high-quality electrotypes.

Conclusion of Donahue V Rodd Electrotype

Donahue V Rodd Electrotype is a versatile and powerful technique that has revolutionized various industries. Its ability to create precise duplicates, enhance durability, and enable intricate designs makes it an invaluable tool. Understanding its principles, applications, and hidden secrets empowers users to harness its full potential, unlocking a world of possibilities.